At the ECM lab at Diesel Control Service Detroit Diesel DDEC 3 and DDEC 4 ECMs are brought to life. Ecm programming and repair work is tested and measured under load and full rpm while firing Detroit Diesel injectors. DDEC III and DDEC IV repair and programming work that gets sent in with an android or iphone number will get a text message with a video or photo of the programmed or repaired ECM running before it ships out.

How the ECM lab has defined our business for the last 9 years.

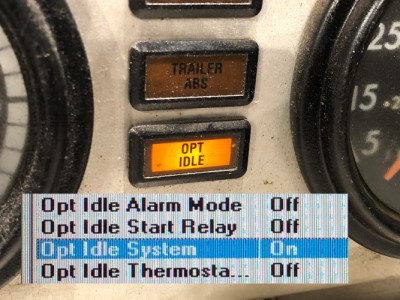

The ECM lab lets us provide transparency you won’t find anywhere else. See a video of your ECM running, watch the cruise control, jake, and fan functions turn on. Check out photos of the inside of the ecm, not just the aluminum box it’s in.

Why DDEC III&IV testing is more important than ever

For those who might not know, Detroit Diesel didn’t manufacture any DDEC III and DDEC IV ecms. Most of these ecms were produced by Motorola for Detroit Diesel from 1993 to 2001 and by 2006 the DDEC IV ECM, it’s circuit board and most of the circuit board components were out of production. Shortly after new replacement DDEC IV ECMs along with replacement DDEC IV circuit boards for Detroit Diesel Remanufactured DDEC IV ecms were no longer available. In other words replacement wasn’t an option for DDEC IVs with damaged circuit boards. So any DDEC III and DDEC IV core ecms with circuit board damage would have to be manually repaired before going back into service as Detroit Diesel remanufactured ecms or be permanently taken out of service and not replaced. Since 2006 the availability and overall condition of these ecms has gotten worse and as of 2024 over 500,000 DDEC III and DDEC IV ecms have been permanently taken out of service. Detroit Diesel reman techs have had to repair damaged circuit boards and replace parts by hand just like everyone else. The work Detroit Diesel reman does is top notch and a remanufactured DDEC IV ecm will get a new ecm case, new ecm connectors and new battery but the circuit board and hundreds of other ecm components will still be the original E01-E06 DDEC IV parts from 1998-2006. Don’t get me wrong Detroit Diesel remanufactured DDEC IVs are the best replacement ecms you can get in 2024 but don’t call them new. When it comes to DDEC III or DDEC IV ecms the difference between “new” and remanufactured/rebuilt/refurbished is the difference between the condition of new plastic body components, laminated sheets, and hair thick copper traces before exposure to 18-30 years of condensation, heat and often fuel/oil contamination, and after exposure. That’s why ecm hardware functionality testing is part of every repair job Detroit Diesel does and part of every repair job we do at the ECM lab. These ECM parts don’t age very fast and as long as they were tested and afterwords kept dry, clean and under 200 degrees they can last a really long time. Many were estimated to last 50 years. If we take care of the DDEC IIIs and DDEC IVs that are left we just might be able to retire before the Series 60 does.

The engine control module (ECM) is without a doubt the most widely misunderstood component on a modern engine. The ECM is the only part of the engine that cannot be easily evaluated. It’s easy to feel if a cylinder liner has been scored. It’s easy to see if a camshaft lobe is flaking but if an ECM is responsible for a no start, misfire or poor fuel mileage or horsepower it’s not easy to be sure the ECM is the problem. Click menu at the upper right corner for more ecm services and associated content